How to Leverage The Potential of All-Solid-State Batteries for Electric Vehicles

Raghav Bharadwaj

Chief Executive Officer

Published on:

07 Dec, 2023

Updated on:

24 Nov, 2025

Electric vehicles (EVs) are quickly becoming the sustainable alternative to gasoline-powered vehicles. However, limited range and long charging times hinder many of today’s EVs. The all-solid-state battery presents a promising solution to these issues.

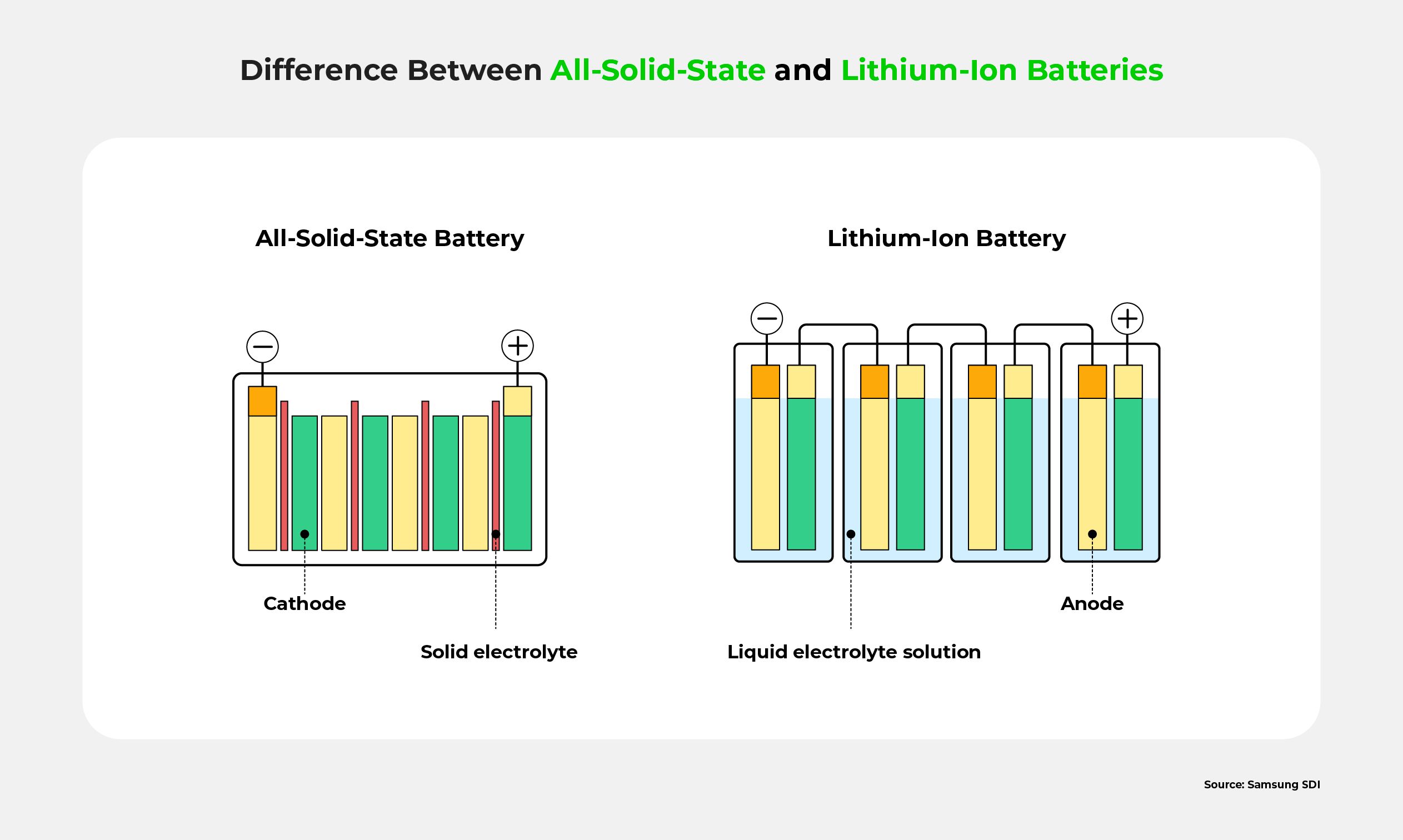

Traditional lithium-ion batteries utilize a liquid electrolyte, which can be flammable and volatile. This raises safety concerns while restricting energy density and charging speed. Conversely, all-solid-state batteries use a solid electrolyte, making them safer, and allowing for higher energy density and faster charging times. All-solid-state batteries are cheaper to produce, utilizing inexpensive materials instead of rare earth metals, setting the stage for broader EV adoption.

To know more about all-solid-state batteries and their potential for EVs, this article answers three questions.

- Why are all-solid-state batteries crucial for EVs and the broader energy landscape?

- What are the challenges to commercializing all-solid-state batteries, and how can we overcome them?

- How will all-solid-state batteries change the future of EVs and energy storage?

Understanding All-Solid-State Batteries

All-solid-state batteries, as the name implies, contain only solid components. Lithium-ion batteries contain two electrodes (a cathode and an anode) separated by a liquid electrolyte. This liquid assists ion movement between electrodes, facilitating electricity generation. Solid-state batteries operate similarly but with a solid rather than liquid electrolyte.

The shift from liquid to solid brings many benefits. Liquid electrolytes require a separator between the cathode and anode, which is redundant in a solid-state context. This compact nature means more energy and capacity, allowing EVs to travel longer distances between charges, reducing the stress of running out of power and searching for charging places.

The lack of flammable liquids in all-solid-state batteries makes them safer and less prone to malfunction, translating to enhanced EV performance.

All-Solid-State Batteries in Today’s EVs Landscape

EV adoption is on a global upswing. By the end of 2023, EVs are projected to account for 18% of all cars sold worldwide. In 2022, over half of three-wheeler registrations in India were electric, and the two-wheeler sector experienced substantial growth in 2022 and 2023.

Currently, EVs almost exclusively use lithium-ion batteries, as it’s the only available option. But, these batteries present many disadvantages:

- Sensitive to temperature, so temperature extremes reduce efficiency or cause permanent damage

- Difficult to recycle and often end up in landfills

- Low energy density requires frequent charging

- Overcharging causes battery damage

- Average lifespan between five to eight years

Most alarmingly, lithium-ion batteries can spontaneously combust when they enter a self-heating state called thermal runaway. These characteristics often increase EV costs and raise safety and range anxiety concerns. However, the emergence of all-solid-state batteries, with their superior safety, two to three times greater energy density, and cost-effectiveness, could revolutionize the EV landscape.

Why Discuss All-Solid-State Batteries Now?

The EV industry is currently navigating several challenges — heightened cost compared to traditional vehicles, safety concerns, and the limited driving range. All-solid-state batteries may be the solution.

Recently, new developments in all-solid-state battery technology can help overcome the limitations of lithium-ion batteries. Toyota unveiled a breakthrough aiming for EVs that offer a 745-mile range with just a 10-minute charge by 2027. Chinese manufacturer Nio is gearing up to launch its solid-state battery with a 150kWh capacity, which is expected to be 40% denser than lithium-ion batteries.

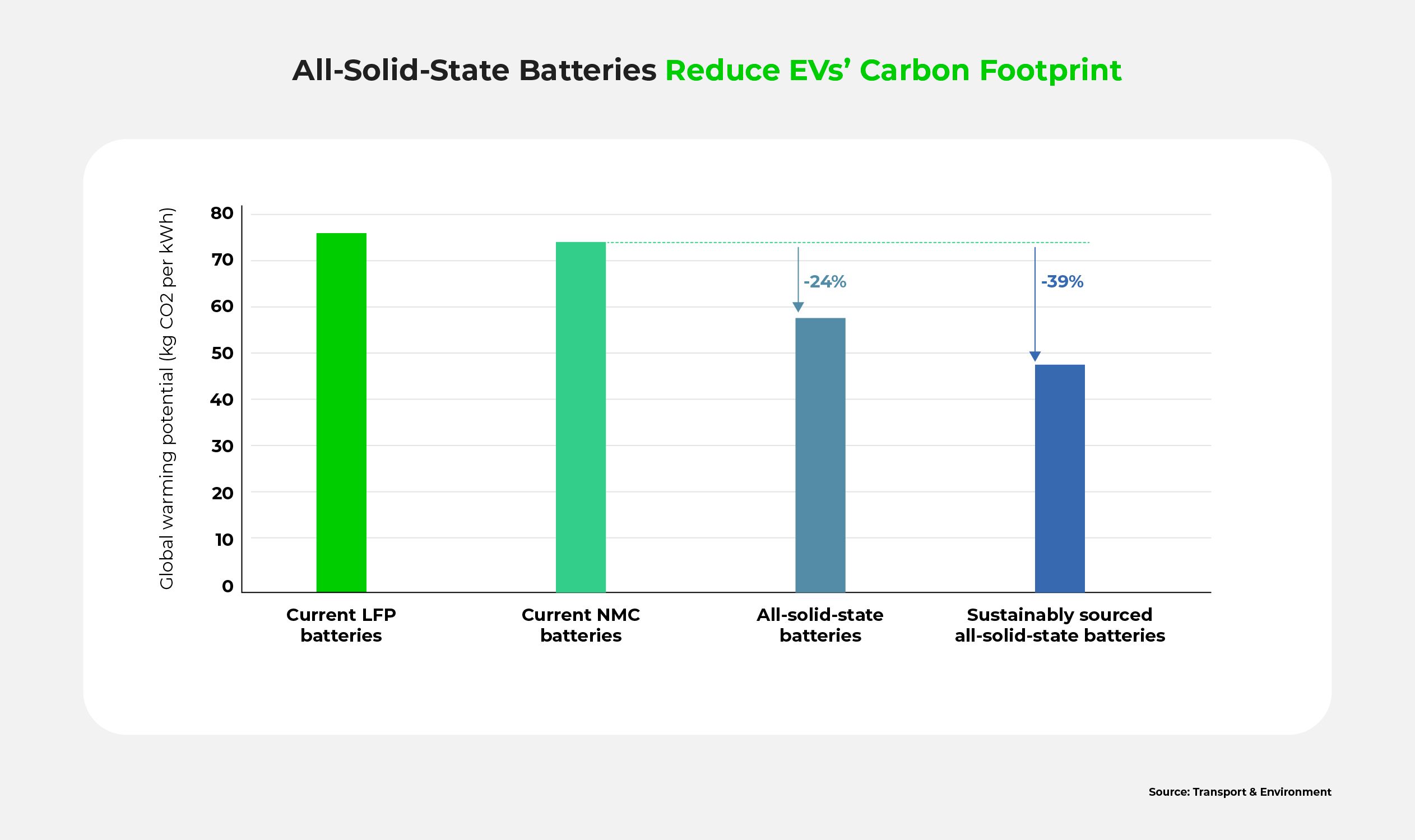

All-solid-state batteries are projected to yield environmental and economic benefits. Estimates suggest these batteries can store more energy with fewer materials, reducing an EV’s carbon footprint by 24%. Research highlights that solid ceramics in all-solid-state batteries can make them lighter, charge faster, and eventually cheaper.

Furthermore, companies like Bolt.Earth are developing advanced operating systems designed to better monitor and manage the underlying Battery Management Systems (BMS) and extend the lifespan of batteries.

However, fully realizing these benefits demands an understanding of inherent challenges.

Challenges in Implementing All-Solid-State Batteries

All-solid-state batteries offer numerous benefits, but their implementation isn’t straightforward. The technology is still emerging, with primary obstacles centered around manufacturing, material identification, and understanding conductivity.

Manufacturing Scalability and Cost-Effectiveness

Many engineering challenges make scalable manufacturing a distant reality. Some processes require external pressure exceeding 100 MPa for cell assembly. Moreover, several studies have used cathodes with less active loading than liquid electrolytes. Further research into the metal plating of anodes and cathodes is essential to understand their morphology and impact on energy density.

Solid-State Electrolyte Conductivity

Measuring the ionic conductivity of solid-state electrolytes is critical and complex. With the current technologies, conductivity is measured as bulk resistance, which can vary based on the electrolyte’s material, frequency, and temperature.

Electrode Material Optimization

The key component in all-solid-state batteries is the solid-state electrolyte, which can be ceramic, glass, polymer, or a mix. The choice of material brings varied electrical, electrochemical, and mechanical variations. Each material can react differently at different temperatures, making it challenging to select the most conducive material. Combining these materials with electrodes is still an obstacle and may need carbonaceous materials.

Despite the difficulties, many companies are researching the potential of all-solid-state batteries for EVs.

Solutions for Advancing All-Solid-State Batteries

Researchers and companies are developing creative solutions to tackle challenges in all-solid-state battery adoption. Through collaborations, government policies, and safety certifications, the world can unlock the potential of cleaner energy storage.

Collaborative Research Efforts

In the last few years, several notable partnerships between research institutions, universities, and corporations have been underway. Some partnerships are:

- Tsuyo Manufacturing and IIT Delhi aim to develop cost-effective solutions using low-cost materials to improve process efficiency and reduce EV prices.

- Indian Oil Corporation and Phinergy, an Israeli battery developer, are manufacturing lightweight metal-air batteries.

- MIT created a new method for stabilizing electrode interfaces, aiding Toyota’s efforts to build all-state-solid batteries.

- A study at Stanford, sponsored by Samsung, alerted manufacturers of aspects to watch out for while using ceramic in all-solid-state batteries.

- Volkswagen and Northvolt, having acquired a cell research company called Cuberg, target a 1000Wh/liter of energy density by 2025.

Such partnerships combine knowledge and perspectives, pushing all-solid-state battery technology forward.

Advancements in Manufacturing Techniques

Innovative manufacturing techniques aim to resolve challenges in making all-solid-state batteries on a large scale. Some significant advancements are:

- Thin-film deposition over solid-state electrolytes provides control over the thickness and uniformity of the electrolyte layer and can help optimize material usage.

- Roll-to-roll processing, where batteries are assembled on a conveyor belt, can support scalable manufacturing.

- Using graphite anodes instead of silicon anodes can increase energy retention and density.

Embracing these methods could create a more extensive all-solid-state battery adoption.

Government Support and Policy Initiatives

Government support and policy initiatives are essential to boost the research and commercialization of all-state-solid batteries. Some policy initiatives are:

- Government funding, in the form of research grants, creates more opportunities for innovation in advancing battery technologies.

- Tax incentives for companies investing in the production of all-solid-state batteries can encourage others to move in this direction.

- Regulations that prioritize the use of all-state-solid batteries can increase their demand and lead to wider EV adoption.

With a mix of financial incentives and a favorable regulatory environment, governments can accelerate the transition to sustainable transportation.

Safety and Certification Requirements

All-solid-state batteries are safer and more efficient when compared to lithium-ion batteries. Still, safety certifications are essential to infuse confidence in the minds of EV owners. Some difficulties in implementing these certification requirements are:

- Depending on the material used as the electrolyte, each kind of solid-state battery can have unique characteristics that may make certification a challenge.

- Ensuring the safety of these batteries requires comprehensive testing across various operating conditions, which may need to be more practical to implement.

- Establishing consistent safety standards across regions is challenging, similar to defining universal traffic rules for safe driving globally.

Despite these challenges, international organizations and governments seek to establish safety standards and certifications.

Safety Measures

Some rigorous safety measures that must be integrated to mitigate the risks of these advanced battery systems are:

- All-solid-state batteries must have fire-resistant casings designed to withstand and contain thermal events.

- All batteries must have sophisticated thermal management systems that will maintain the battery’s temperature within safe limits, preventing potential hazards.

- A battery management system (BMS) must continuously monitor the battery’s performance and initiate shutdown when irregularities arise.

These measures are a starting point to infuse safety as an integral part of battery manufacturing.

Certification Standards

Certifications are essential to ensure the safety and reliability of all-solid-state batteries, especially for EVs. Some possible standards are:

- The UN 38.3 regulation evaluates the safety of lithium batteries and involves electrical, mechanical, thermal, and environmental testing.

- The IEC 62660-1 standard outlines the requirements for lithium-ion batteries and addresses factors like electrical performance, thermal management, and safety features.

- The UL 2590 standard is specifically geared for the safety and performance of EV battery packs, as it assesses factors like thermal runaway prevention, electrical insulation, and protection against external hazards.

These certification standards can also be extended to all-solid-state batteries, acting as benchmarks for their safety and reliability.

Advancing Electric Mobility with All-Solid-State Batteries

All-solid-state batteries are poised to redefine electric mobility. With enhanced energy density, they promise longer driving ranges and faster charging speeds, making EVs appealing to consumers. This boost in performance and reduction in greenhouse gas emissions presents a cleaner and more sustainable transportation future.

Ongoing research and development are crucial to fully harness the potential of all-solid-state batteries. As the technology continues to improve and gain accessibility, it will play a pivotal role in shaping the EV market, driving sustainability efforts, and accelerating the global transition to cleaner energy sources. The future is bright, with all-solid-state batteries leading the way towards a greener and more efficient world of electric mobility.

To learn more about all-solid-state batteries, please see the FAQ and Resources below!

FAQ

What are all-solid-state batteries, and how do they differ from conventional lithium-ion batteries?

All-solid-state batteries use only solid materials as electrolytes, typically ceramics or polymers, unlike the liquid electrolytes found in lithium-ion batteries. This solid-state design offers several advantages, including higher energy density, faster charging capabilities, improved safety due to reduced risk of thermal runaway, and potentially a longer lifespan.

What advantages do all-solid-state batteries offer for electric vehicles?

All-solid-state batteries offer several advantages for EVs. They provide higher energy density, enabling longer driving ranges. They also allow faster charging is possible due to improved ion conductivity in solid-state electrolytes. Enhanced safety is a key benefit, as these batteries are less prone to thermal runaway. Additionally, they have the potential for a longer lifespan, reducing the need for frequent battery replacements, which is particularly important in the automotive industry.

What are the main challenges in developing and commercializing all-solid-state batteries for electric vehicles?

Developing and commercializing all-solid-state batteries presents significant challenges. Scaling manufacturing to meet the rising demand for EVs is difficult given the many variations in solid electrolytes. Additionally, finding electrode materials that maximize energy density and cycling stability is a technical challenge that requires innovative solutions.

How are safety concerns of all-solid-state batteries in EVs addressed?

Safety measures are being rigorously implemented to address concerns related to all-solid-state battery usage in EVs. These measures include using fire-resistant housing to contain thermal events and reduce external fire risks. Sophisticated thermal management systems are engineered to prevent overheating, ensuring safe battery operation within optimal temperature ranges. Furthermore, intricate battery management systems (BMS) continuously monitor battery performance. In the event of anomalies or irregularities, the BMS can promptly initiate shutdown procedures, significantly enhancing overall safety and reliability.

How do all-solid-state batteries impact the performance and range of electric vehicles?

All-solid-state batteries have higher energy density, allowing for increased energy storage capacity resulting in longer driving ranges on a single charge. Additionally, the enhanced efficiency of these batteries can lead to improved acceleration and sustained performance over time. These factors make all-solid-state batteries a promising technology for boosting EV performance and competitiveness.

Resources

MDPI: Recent Advances in All-Solid-State Lithium–Oxygen Batteries: Challenges, Strategies, Future

Discover the future of all-solid-state batteries.

LinkedIn: Unveiling the potential of all-solid-state batteries in shaping the future of electric vehicles

Learn how all-solid-state batteries are paving the way for a bright future for EVs.

Wiley Online Library: Challenges, interface engineering, and processing strategies toward practical sulfide-based all-solid-state lithium batteries

Gain an in-depth understanding of all-solid-state lithium batteries.

Association for Computing Machinery: The Holy Grail of Electric Vehicles: Solid-State Batteries

Explore how all-solid-state batteries can impact EVs.

OSTI.gov: High-Efficiency, Medium-Voltage-Input, Solid-State-Transformer-Based 400-kW/1000V/400A Extreme Fast Charger for Electric Vehicles

Stay informed of key developments in solid-state batteries for EVs.

Feb 19, 2026 • EV Charging Infrastructure

EV Charging for Quick Commerce Fleets in India: Scaling Sustainable Delivery

Read More

Feb 17, 2026 • EV Charging Infrastructure

The Psychology of EV Charging: What EV Drivers Want at a Charging Station

Read More

Feb 12, 2026 • EV Charging Infrastructure

What Is the Real Bottleneck in Scaling India’s EV Charging Network?

Read More