Implementing DC Fast Charging: A Fleet Manager’s Guide

Raghav Bharadwaj

Chief Executive Officer

Published on:

05 Nov, 2025

Updated on:

10 Feb, 2026

For fleet managers electrifying (or expanding) their EV fleets, designing the right fast charging setup is just as important as selecting the right vehicles. This blog provides a step-by-step framework and tips to help you choose a DC fast charging solution that maximizes uptime and return on investment (ROI).

1. Assess Your Fleet’s Duty Cycles and Energy Needs

Start by analyzing your fleet’s daily operations. What is the average distance per vehicle? What are the peak operating hours vs. idle periods? What are the typical range requirements and downtime windows?

For example, if delivery vans cover 120 km daily and return to the warehouse twice for loading, those loading periods might be ideal for quick charging. A van consuming 1 kWh per 5 km would need approximately 24 kWh per day. Multiply this by your fleet size to estimate total daily energy demand.

A useful rule: Segment vehicles based on charging needs. For example, vehicles with around-the-clock availability or very high daily mileage will likely require DC fast chargers, not just overnight slow charging. Identify which vehicles absolutely need fast charging to meet the schedule (e.g., those with <4-5 hours idle time in 24 hours) and which can suffice with slower charging.

2. Choose the Right Charger Power Levels

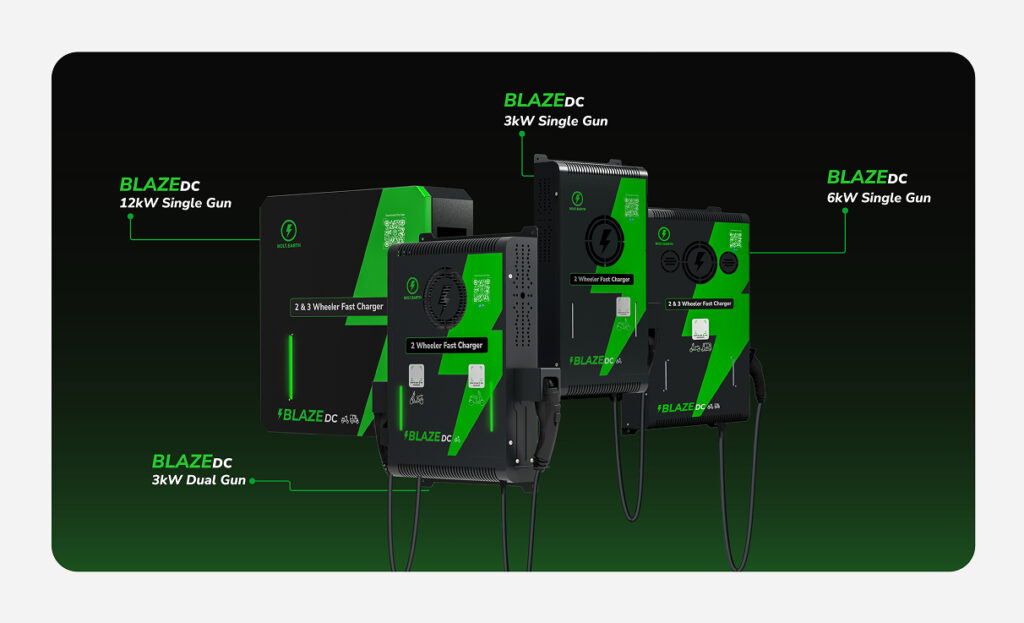

Small EVs like 2- and 3-wheelers (2–10 kWh batteries) need only 3–12 kW chargers—enough for a full charge in under an hour. Most two-wheelers can’t handle high currents.

Three-wheelers and small cargo EVs (10–20 kWh) charge efficiently at 15–30 kW, reaching full capacity in 30–60 minutes.

Fleet cars and vans (20–40 kWh) typically support 30–60 kW DC fast chargers, adding approximately 100 km of range in an hour, or up to 80% in less than one.

Larger trucks and buses (100 kWh+) need at least 60 kW, ideally 90–210 kW for faster turnarounds.

City e-buses in India typically use 120 kW chargers, while intercity buses and heavy trucks are adopting 360 kW CCS2 and upcoming megawatt charging systems. Since higher power means higher cost and grid demand, a mix works best: a few 100 kW units for large vehicles and multiple 30 kW units for routine fast charging.

Ensure compatibility with connector standards. To future-proof your setup.

3. Determine Number of Chargers and Charging Ports

Estimate how many vehicles need to be charged simultaneously. Fleet EVs often share chargers due to staggered charging schedules. One fast charger can typically serve 5-10 vehicles with managed scheduling.

For example, if 10 taxis each need a 30-minute top-up across an 8-hour shift, two 50 kW chargers could handle all 10. But if 20 delivery vans return at 7 PM and must leave by 8 PM, more chargers will be required.

As a rule of thumb, start conservatively (3:1 or 4:1) and adjust using real-world usage data, though high-utilization fleets may need ratios closer to 1:1 or 2:1. Consider dual-gun chargers that can charge two vehicles at once or split power dynamically (e.g., two 30 kW outputs from a 60 kW unit).

Plan your layout for easy cable access and charger reach. Finally, always use at least one extra charger for redundancy in your fleet charging solution.

4. Plan Infrastructure and Power Supply

Collaborate early with your electricity provider and engineers to confirm your site can handle the required load. For example, three 60 kW chargers running together require 180 kW; your connection and transformer must support this load alongside other facility needs. Use load management systems to stay within capacity. If you have four 60 kW chargers (240 kW total) but only a 180 kW connection, smart software can dynamically distribute power to avoid overload.

Consider on-site solar and battery energy storage (BESS) to reduce grid demand and costs. Storage can charge during off-peak hours or from solar, then deliver high power during peak use, easing grid pressure and providing backup during outages.

In the EV charging infrastructure in India, solar + storage systems can make daytime fast charging cleaner and cheaper.

If mission-critical uptime is essential, include backup power, such as a diesel genset or battery pack, for emergency charging. While diesel backup isn’t ideal for the long term, it ensures operational continuity when the grid fails.

5. Ensure Charger Uptime and Maintenance

Fast charging only adds value when chargers are reliable. Invest in robust, well-supported equipment with remote monitoring and strong service contracts.

Best practices include:

- Preventive maintenance, regular inspections, calibration, and timely replacement of wear parts.

- Keep essential spares like cables, connectors, and fuses handy to minimize downtime.

- Train in-house staff or contract an on-call technician for quick fixes, and consider an O&M contract with guaranteed uptime (e.g., SLA to resolve faults within 24 hours).

- Always plan for redundancy; if one charger can meet your fleet’s needs, install at least two to prevent total disruption.

As your fleet grows, distribute chargers across sites to avoid single-point failures. With proper monitoring, predictive maintenance, and real-time monitoring, 95–98% uptime is achievable. Treat chargers like critical IT infrastructure, actively managed and maintained.

6. Use Software to Optimize Charging and Costs

A centralized charging management platform can automate scheduling, prioritize vehicles, and notify drivers when charging is complete.

For larger fleets, integration with EV fleet management solutions helps align charging with vehicle deployment.

Smart scheduling also reduces electricity costs by shifting non-urgent charging to off-peak tariff hours (like 6–10 PM). Advanced systems can reallocate power from nearly full vehicles to those needing faster charging, maximizing utilization.

In India, many fleets already use these strategies; charging more vehicles simultaneously at moderate power often beats waiting for high-speed slots. Smart software ensures every kilowatt is used efficiently.

7. Analyze Costs and Track ROI

Before installation, conduct a full total cost of ownership (TCO) and EV charging ROI analysis covering equipment, installation, grid upgrades, maintenance, and electricity costs. Balance these against savings, lower fuel and vehicle maintenance costs, operational uptime gains, and any carbon credits or incentives. This helps estimate your payback period.

Many fleet charging projects in India recover costs within a few years; high-utilization public stations can even break even in under two days. For private fleets, the “return” often comes from fuel savings and improved productivity.

If ROI looks tight, adjust your plan; fewer chargers, more overnight AC charging, or smarter utilization can improve payback. Aim for 30–50% charger utilization during working hours to strike the right balance between capacity and efficiency.

Also, explore financing or leasing models, now offered by several banks and charge-point operators. Spreading costs over time through “charging-as-a-service” makes infrastructure investment easier and ROI more attractive.

8. Future-Proof and Scale Your Setup

Plan your charging setup with growth from the start. As EV adoption rises, expanding your fleet and charging needs will be inevitable. It’s far cheaper to prepare now than retrofit later.

When installing electrical infrastructure, lay conduits for future chargers and install a slightly larger transformer in case the fleet size may double in a few years.

Choose modular chargers that scale easily. Reserve space and electrical capacity upfront to avoid expensive overhauls later.

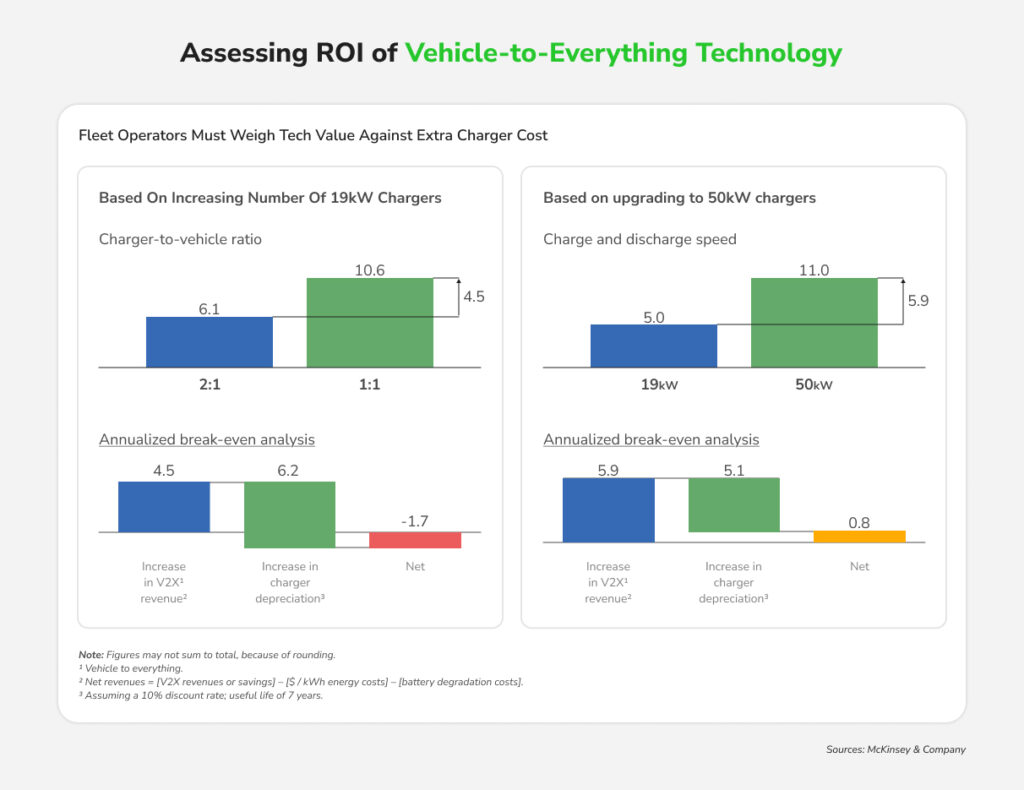

Stay informed on emerging technologies like 500 kW+ chargers and vehicle-to-grid (V2G) systems. If relevant, invest in V2G-ready chargers to unlock future revenue opportunities.

Finally, ensure all chargers support open standards like OCPP to maintain software flexibility and avoid vendor lock-in. The goal: build a system that grows and evolves seamlessly as your fleet and technology advance.

Final Thoughts

By understanding your fleet’s needs, right-sizing your charger mix, building a resilient infrastructure, and using smart management software, fleet managers like you can deploy DC fast chargers in a cost-effective way that delivers real uptime and ROI. Indian pioneers, from e-commerce giants to electric taxi startups and state transport fleets, have proven it’s possible. Their success came not just from adopting EVs but from building the charging muscle behind them.

Frequently Asked Questions

How do I decide which vehicles in my fleet actually need DC fast charging?

Not all EVs need DC fast charging. Analyze duty cycles and downtime windows. If a vehicle operates almost continuously (e.g., <4–5 hours idle per day), it needs DC charging to sustain uptime. Vehicles with predictable overnight rest can rely on slower AC charging. A good strategy is to segment your fleet by usage intensity. High-mileage or high-availability vehicles get fast chargers; the rest use slower, cheaper options.

How do I calculate how many chargers my fleet actually needs?

Estimate total energy demand (kWh/day) and overlapping idle times. A 3:1 or 4:1 vehicle-to-charger ratio works for most medium-utilization fleets, but for 24×7 operations, go closer to 1:1 or 2:1. Also, always install at least one redundant charger for continuity.

What kind of maintenance plan ensures 95%+ uptime?

Follow preventive maintenance every quarter, cable inspection, firmware updates, and part replacements (connectors, relays, fans). Keep critical spares on-site, train one technician, and use remote diagnostics for quick fault resolution. Aim for an Operation and Maintenance Service Level Agreement (O&M SLA) guaranteeing 24-hour resolution; treat chargers like IT servers, not just equipment.

Feb 19, 2026 • EV Charging Infrastructure

EV Charging for Quick Commerce Fleets in India: Scaling Sustainable Delivery

Read More

Feb 17, 2026 • EV Charging Infrastructure

The Psychology of EV Charging: What EV Drivers Want at a Charging Station

Read More

Feb 12, 2026 • EV Charging Infrastructure

What Is the Real Bottleneck in Scaling India’s EV Charging Network?

Read More